Success Stories

News from the Network

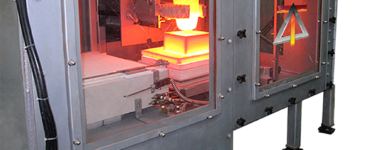

Massive Changes Result in Massive Results for Western Colorado Manufacturer

Read full storyBut Wood it Work? A Colorado Couple Finds Success in Wood and Words

Read full storyWedgewood Cabinetry: A seasoned business with a fresh approach

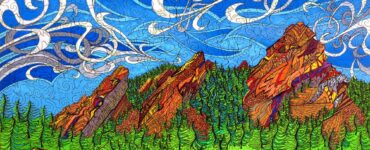

Read full storyLiberty Puzzles: Where Modern-Day Manufacturing Meets Artisan Traditions

Read full storyMaking Waves in Sustainable Hybrid Women’s Athleticwear

Read full storyVeterinary Doctors Find Their Way to the Manufacturing Floor

Read full storyColorado-Based Natural Skincare Company Spinster Sisters Turns to Local MEP Center to Increase Throughput and Meet Hand Sanitizer Demand

Read full story